1946

–

CELEBRATING GREAT BRITISH INNOVATION

Marshall Motor Group

Expands

Marshall opened a garage in Peterborough in 1946, its first outside Cambridge, before expanding to Bedford and other neighbouring towns.

Around the same time, Marshall moved into building bodies for buses and lorries. The venture provided additional employment for the aviation workforce, following a reduction in demand since the war.

Partnering with

British car brands…

Marshall expanded the range of cars it sold to include some of the most well-known British marques.

Partnering with

British car brands…

Marshall expanded the range of cars it sold

to include some of the most well-known British marques.

….and some of the world’s

top aircraft manufacturers

After the war, aviation engineering work at Marshall continued to generate new business, which called for the construction of a new concrete runway and large hangers.

Most of this work involved repairs, structural modifications and conversions.

Marshall also developed its aircraft design and manufacturing facilities, becoming a trusted sub-contractor to the biggest aircraft manufacturing companies.

….and some of the world’s

top aircraft manufacturers

After the war, aviation engineering work at Marshall continued to generate new business.

Most of this work involved repairs, structural modifications and conversions.

Marshall also developed its aircraft design and manufacturing facilities, becoming a trusted sub-contractor to the biggest aircraft manufacturing companies.

Did you know?

Marshall modified a number of Vickers aircraft including the Valiant, Viking, Varsity, Valetta and the Viscount – the first turbo-prop airliner in the world.

Round

the world

In 1948, a 24-year-old Cambridge local, Richarda Morrow-Tait, became the first woman to pilot a plane around the world. Richarda learned to fly at Cambridge Airport’s Aero Club, and then began her year-long round the world journey at Cambridge Airport, flying from there to the official start at Croydon.

Did you know the Aero Club at Cambridge Airport is still open for business, having been teaching people to fly since 1930?

Richarda “Dikki” Morrow-Tait. Image appeared on page 1 of the May 21, 1949 issue of the Star Tribune.

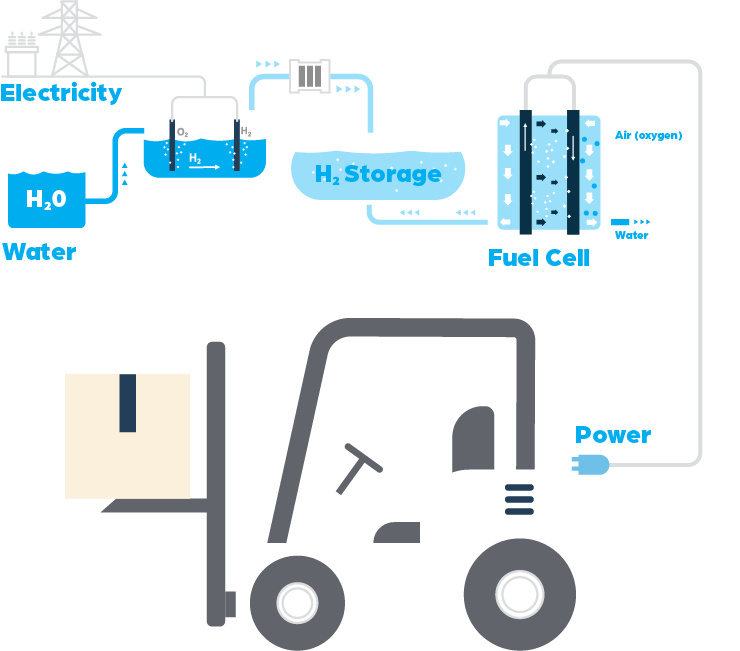

Fuelling the future

In 1957, Marshall SV worked closely with the National Research and Development Corporation and Francis Thomas Bacon, the inventor of the fuel cell.

Together, they successfully developed a 6kW fuel cell powered by hydrogen and oxygen – which was demonstrated on an electrical forklift truck.

This technology was later developed by American aerospace manufacturer Pratt & Whitney to help power the Apollo 11 moon landing.

Michael Marshall

1932-2019

Sir Michael Marshall, Arthur Marshall’s eldest son, was born January 1932, and educated at Jesus College, Cambridge. A keen rower, he gained his Rowing Blue as the Cambridge stroke in the 1954 Boat Race and rowed for Great Britain.

Sir Michael completed his National Service as a pilot in the Royal Air Force before joining the family business in 1955. He was appointed Managing Director of Marshall of Cambridge (now Marshall Motor Group) in 1963, and Deputy Chairman of the Marshall Group of Companies in 1965. Following his father’s retirement, he became Group Chairman and Chief Executive in 1989.

Sir Michael was awarded a CBE in the 1999 Queen’s Birthday Honours and a knighthood in the 2010 New Year’s Honours.

Michael Marshall

1932-2019

Sir Michael Marshall, Arthur Marshall’s eldest son, was born January 1932, and educated at Jesus College, Cambridge. A keen rower, he gained his Rowing Blue as the Cambridge stroke in the 1954 Boat Race and rowed for Great Britain.

Sir Michael completed his National Service as a pilot in the Royal Air Force before joining the family business in 1955. He was appointed Managing Director of Marshall of Cambridge in 1963. Following his father’s retirement, he became Group Chairman and Chief Executive in 1989.

Sir Michael was awarded a CBE in the 1999 Queen’s Birthday Honours and a knighthood in the 2010 New Year’s Honours.

1960

–

On the ground and in the air

A boom time

on Britain’s roads

Using its team of skilled fitters, Marshall went on to build over 90,000 commercial vehicle bodies.

Marshall commercial vehicle work included:

Marshall also built car transporters, including for Formula 1’s John Player Team Lotus racing cars.

Keeping the

military moving

And it wasn’t just commercial businesses that Marshall was helping keep on the road.

By the start of the 1960s, Marshall had already delivered its 10,000th cargo vehicle to the Ministry of Supply.

Busy

making buses

In the years after the war, Marshall rebuilt London’s fleet of double decker buses. From this, a thriving bus manufacturing business grew. Counties up and down the UK relied on buses from Marshall for their local bus networks.

In 1959, Marshall bought Mulliners, a specialist in buses suited for rough terrain. Around 25% of buses made by Marshall were exported to 30 different countries, including Argentina, Indonesia, and Sudan.

Busy

making buses

After the war, Marshall rebuilt London’s fleet of double decker buses. From this, a thriving bus manufacturing business grew. Counties up and down the UK relied on buses from Marshall for their local bus networks.

In 1959, Marshall bought Mulliners, a specialist in buses suited for rough terrain. Around 25% of buses made by Marshall were exported to 30 different countries, including Argentina, Indonesia, and Sudan.

Relationship

with the RAF

In 1966, Marshall became the UK’s designated company for the RAF C-130K Hercules, introducing the aircraft to RAF service.

Marshall became a ‘Sister Design Authority’ in the RAF fleet of C-130s until their retirement from service in 2023.

Did you know?

In 2013, Marshall received a  Chief of the Air Staff’s Commendation from the RAF

Chief of the Air Staff’s Commendation from the RAF after we urgently repaired five C-130J planes on the ground in Afghanistan when they had suffered extensive hailstone damage during a storm. The hailstones were the size of golf balls.

after we urgently repaired five C-130J planes on the ground in Afghanistan when they had suffered extensive hailstone damage during a storm. The hailstones were the size of golf balls.

Did you know?

In 2013, Marshall received a Chief of the Air Staff’s Commendation from the RAF after we urgently repaired five C-130J planes on the ground in Afghanistan when they had suffered extensive hailstone damage during a storm. The hailstones were the size of golf balls.

An

aviation

icon

The British Aircraft Corporation commissioned Marshall to deliver the design and manufacture of the iconic Concorde drooping nose and retracting visor in 1967.

Did you know?

The Concorde’s drooping nose was lowered by pilots during taxi, take-off and landing to improve visibility, and returned to a horizontal position during flight to achieve optimal aerodynamic efficiency.

Transforming

the food supply chain

In 1972, Marshall extended its expertise on the roads, founding a refrigeration, tail lift and commercial vehicle fleet service and support organisation.

Launched initially as Marshall Thermo King, the company quickly established the UK’s largest transport refrigeration service based around the global Thermo King brand.

Now known as Marshall Fleet Solutions, today, the company supports some of Britain’s largest supermarket chains 24/7, 365 days a year with over 100 fully equipped mobile engineers.

Transforming

the food supply chain

In 1972, Marshall extended its expertise on the roads, founding a refrigeration, tail lift and commercial vehicle fleet service and support organisation.

Launched initially as Marshall Thermo King, the company quickly established the UK’s largest transport refrigeration service based around the global Thermo King brand.

Now known as Marshall Fleet Solutions, today, the company supports some of Britain’s largest supermarket chains 24/7, 365 days a year with over 100 fully equipped mobile engineers.

Sleds

in space

Marshall’s diverse manufacturing abilities were demonstrated in 1963 when the company received an order from RAE Farnborough to manufacture timber sleds on rails to test ejector seats for aircraft.

The sleds were powered by rocket motors – and capable of accelerating to 500 mph.

In 1978, Marshall won a contract from the European Space Agency to design and manufacture a space sled for medical research – to help alleviate space motion sickness experienced by some astronauts.

The space sled made 121 orbits of Earth on board the Space Shuttle Challenger in 1985.

1980

–

Stepping up to new challenges

A stretching project

What do you do if your transporter plane isn’t quite big enough? You stretch it!

Between 1980 and 1985, Marshall extended the fuselage of 30 C-130 planes, adding an extra 4.5m of length to each.

A stretching project

What do you do if your transporter plane isn’t quite big enough? You stretch it!

Between 1980 and 1985, Marshall extended the fuselage of 30 C-130 planes, adding an extra 4.5m of length to each.

Falklands War

In February 1982, two months before the start of the Falklands War, Marshall received an order from the Ministry of Defence: make inflight-refuelling possible for RAF Hercules C130s.

Marshall installed revolutionary air-to-air refuelling receiver equipment, enabling Expeditionary Forces to travel the 8,000 miles needed to reach the Falkland Islands.

Did you know?

This vital modification was designed, manufactured, installed and flight-trialled within 14 days, and in service three weeks from the initial design request.

Gulf War

Marshall maintained and modified the RAF TriStars, which played a key role in the 1990-1991 Gulf War.

To help camouflage the planes against the Middle East landscape, Marshall painted two Tristars desert pink overnight.

Did you know?

The Tristars were painted pink using rollers from B&Q.

Chariots of Fire

This charity race, which follows in the footsteps of the famous film Chariots of Fire, first took place in Cambridge in 1992, where 77 teams raised £17,000.

As a veteran of the 1924 Olympic team celebrated in the film, Sir Arthur Marshall was the event’s Honorary President for many years until his death in 2007. His son, Sir Michael Marshall, took over the role for the remainder of his life.

The event continues to this day – having raised over £1.5M for local and regional charities.

Saving lives

in the field

In 1999, Marshall was awarded the contract to develop a modular transportable surgical facility for the Ministry of Defence. State-of the-art surgical facilities could now be deployed in critical situations.

Since then, Marshall has gone on to develop modular field hospitals, mobile laboratories, and even a deployable CT scanner.